Description

Rob Allen Premade 16mm Green Bands

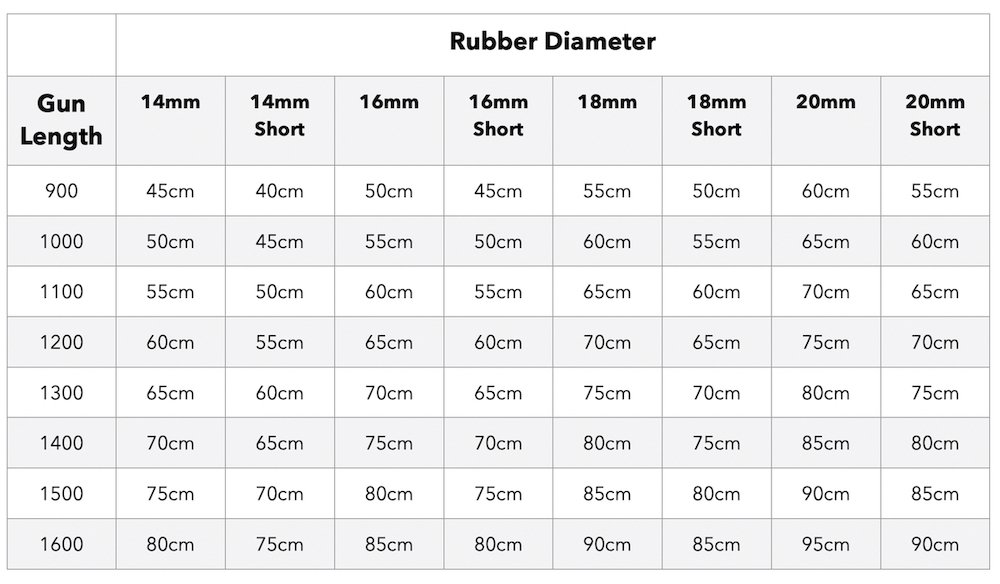

The Rob Allen Premade 16mm Green Bands are made from coated latex which allows the rubber to last longer, plus the highest grade Dyneema bridle.

Made up in-store by our staff, we save you the time and effort of making them yourself. You can of course also choose to make your own bands with a Bridle D.I.Y kit, however we understand that you may not have the tools, time or skills, so we have pre-made these to help.

We insert the Rob Allen dyneema bridle into the rubber and tie it off with a constrictor cord. This is then used to hook on to your spear’s notch for loading.

Pre-made bands are perfect as spare parts to keep in your bag, whether you go on a longer spearfishing trip or just a day trip.

Even a day trip? Oh yes – because once you’re on the water, you’re always far from any shops.

Also available as 14mm premade bands.

Features:

- Coloured outer layer increases the protection from the environment.

- Rubber manufactured in the USA by dip processing

- Pre-tied and ready to go straight onto your muzzle.

- Without question one of the best rubbers.

- Perfect for spare rubbers on trips.

- Ready to use straight away.

Are you using twin rubbers?

If you’re using a twin rubber setup, we recommend going one size up for ease of loading and improved accuracy.

Example: if your speargun is 80cm (800mm) long, we recommend to order two 900mm bands.

Always struggling to load your speargun?

Call us during shop hours and we’ll work out the best setup for you.

Reviews

There are no reviews yet.