Description

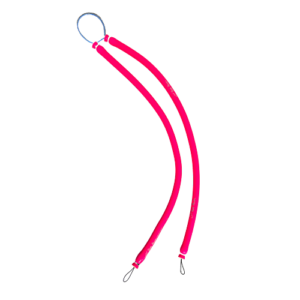

Rob Allen Premade 14mm Black Roller Bands

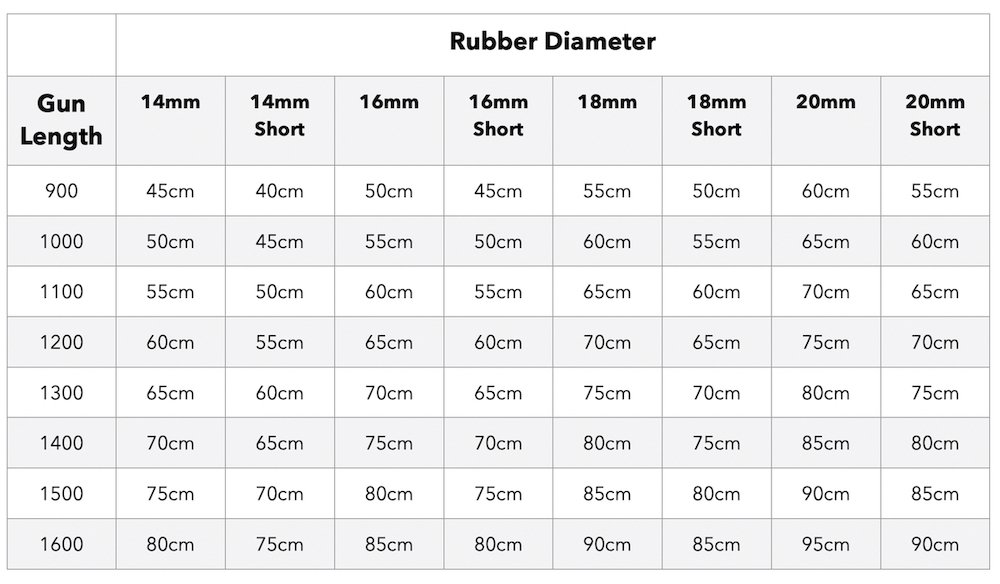

The Rob Allen Premade 14mm Black Roller Bands suit all roller guns (select size in options).

Made up in-store by our staff, we save you the time and effort of making them yourself. You can of course also choose to make your own roller bands with a Bridle D.I.Y kit, however we understand that you may not have the tools, time or skills, so we have pre-made these to help.

Made from genuine Rob Allen 14mm rubber and dyneema. High-quality dyneema bridles and inserts with beads ensure there are no failures.

Rob Allen manufacture their spearfishing rubber by dip processing. While costing more, this allows using fewer additives, enhancing performance on a gun. The coloured outer layer increase protection from the environment, and the amber inner core is purer for performance.

Trials and tests have shown this rubber to provide up to 40% greater strength than other manufacturers.

Always struggling to load your speargun?

Call us during shop hours and we’ll work out the best setup for you.

Reviews

There are no reviews yet.