Description

Rob Allen 16mm Blue Rubber

The Rob Allen 16mm Blue Rubber is manufactured by Dip processing. While costing more this enables fewer additives to be used, enhancing performance on your speargun.

The coloured outer layer increase protection from the environment and the amber inner core is purer for performance.

All our bulk rubber is sold per 1 meter.

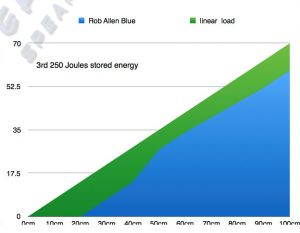

Trials and tests have shown this rubber to provide up to 40% greater strength than other manufacturers, as the chart below shows:

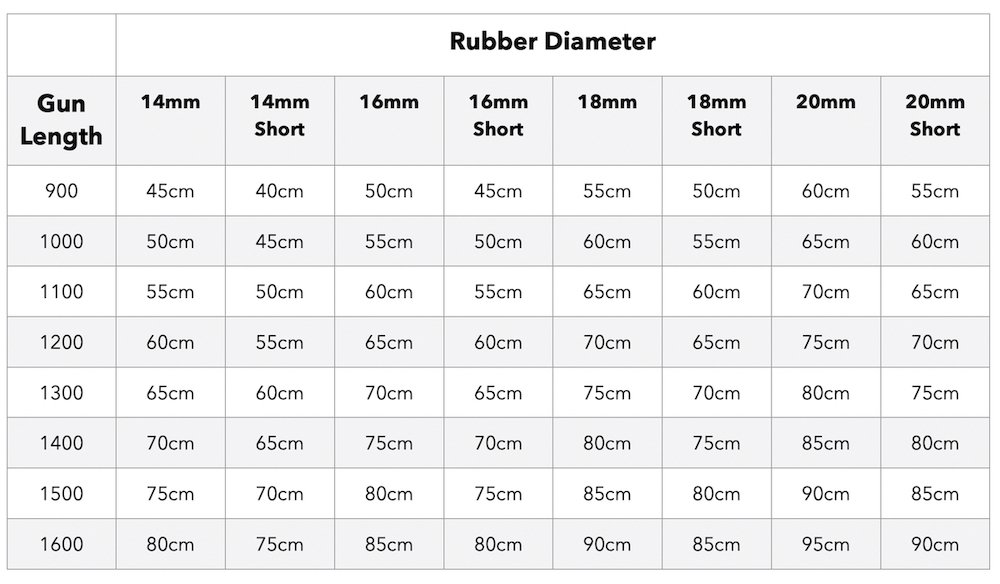

Not 100% sure which Rob Allen 16mm Rubber length you need for your speargun?

- Measure your speargun from top to handle,

- Find the number in the rubber size guide below:

GTIN 9330181016899

Reviews

There are no reviews yet.